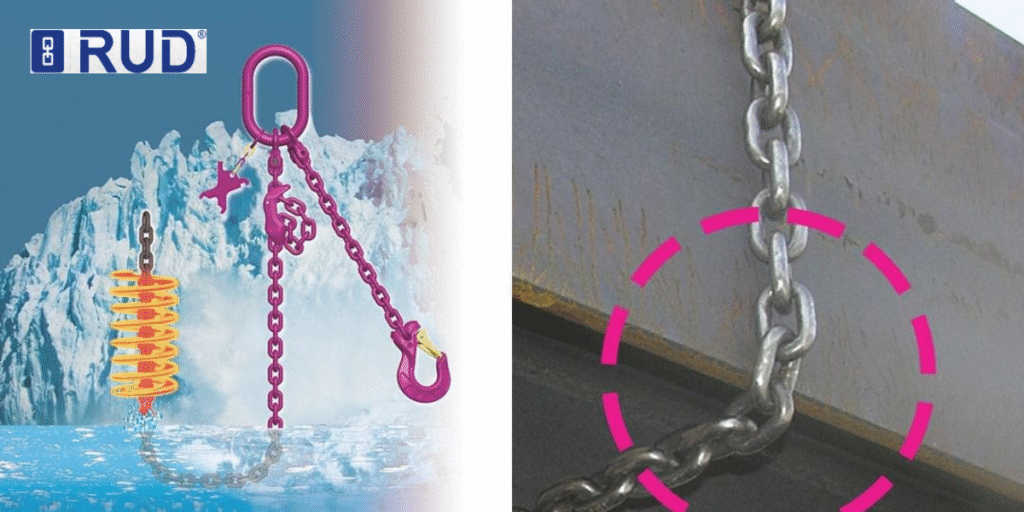

Both ICE and VIP chain systems deliver reliable lifting performance for heavy loads, but they differ in material grade, component design, and maintenance needs. RUD Chains manufactures the ICE Grade 120 and VIP Grade 100 systems at its Brisbane facility, with each designed for specific mining applications.

While ICE uses higher-grade steel for maximum load capacity in tight spaces, VIP has modular components that swap out faster during breakdowns.

Now you might be wondering which system actually fits your operation. Frankly, the answer depends on your site’s load requirements, available space, and how your maintenance crew handles repairs when chains need work.

Let’s start with how they differ.

What Makes ICE and VIP Chain Systems Different

Simply put, the main split comes down to steel grade and how that affects everything else in your lifting setup.

ICE uses Grade 120 material for higher working load limits in extreme mining conditions (keep the strength-to-size ratio in mind!). So, you get a 10mm Grade 120 chain handling loads that would typically need a 13mm Grade 100 chain to match. That difference becomes important when you’re working inside confined underground spaces or need to fit components through tight access points.

On the other hand, VIP Grade 100 components cost less upfront and swap out faster when maintenance is needed. The modular design means your crew can replace damaged sections without taking the entire sling out of service.

You’ll also find that Grade 100 parts are more common across Australian suppliers, which means less downtime when you need quick replacements.

Material grade affects component compatibility and replacement expenses throughout the system’s working life. You can’t mix ICE and VIP parts in the same assembly (and yes, we’ve all seen the “close enough” approach backfire spectacularly).

Each class requires matching fittings to maintain proof load ratings and meet Australian Standards regulations. Once you know the grade difference, it helps to see what’s actually in each system.

Breaking Down ICE Chain System Components

ICE components give you maximum strength in a compact package, which is exactly what mining operations need when space runs tight. And since it’s designed around Grade 120 steel, every single part works together without compatibility issues.

Let’s break it down, shall we?

Chain Links and Construction

Welded Grade 120 links handle extreme underground conditions where chains face constant abrasion and heavy loads. The welding process uses electric resistance technology that fuses each link without creating weak points in the metal structure.

Every weld gets inspected during manufacturing to meet specifications before leaving the facility. This way, chains maintain consistent strength across every link in the assembly.

Master Links and Connectors

Every fitting meets Grade 120 specs, from the master links down to the smallest connecting devices. Take a typical mining sling working in a Queensland coal operation: the hooks, links, and attachments all carry the same material grade rating.

Component compatibility prevents weak points when you attach different parts. You won’t find mismatched grades supplied in our systems, which means predictable performance across the entire lifting solution.

Understanding VIP Chain System Parts

Ever had a chain snap mid-shift and wished you could fix it without calling the specialists? That’s the exact problem VIP systems solve with their modular design approach.

The whole system is built around making field repairs faster and easier for your maintenance crew. Here’s what we mean by that:

● Mechanical connections: VIP uses coupling links instead of welded joints, which means you can disconnect and reconnect parts right on site. It speeds up field repairs so production keeps running without interruption.

● Modular sections: Swap damaged parts without replacing full assemblies during breakdowns. From our extensive work with mining operations, we’ve seen how VIP’s modular design cuts repair time in half. One Queensland site even replaced a worn section in under an hour, compared to the full day they’d need for a complete sling replacement.

● Grade 100 construction: As we’ve mentioned before, reliable performance with easier sourcing across Australian suppliers means you’ll find replacement components faster.

● Quick adjustments: No welding gear is needed on site when you need to modify sling lengths or swap components (because waiting three days for a welder in the middle of nowhere gets expensive fast). Remote mining equipment wears out faster and is more prone to failure, so easy field repairs are essential.

Now that you understand how each system is built, the next question becomes how they actually perform under load.

Load Ratings and Proof Load Testing Standards

So what’s the real deal with proof load testing? Basically, it gives you documented proof that components exceed normal working conditions.

| System | Grade | Test Load | WLL Advantage |

| ICE | 120 | 2x WLL | Higher capacity, same size |

| VIP | 100 | 2x WLL | Standard capacity, lower cost |

Both systems get proof tested to twice their working load limits before they reach your site (that’s not a suggestion, it’s a manufacturer’s requirement). The proof load test applies a controlled force to verify each component can handle loads well beyond what you’ll use in daily operations.

Plus, certain certificates provide traceability for audits and show exactly what load was applied to each batch. Our testing facility in Brisbane puts every component through rigorous proof loads, and the results consistently show why material grade is important for your lifting operations.

Matching the Right System to Your Site

Let’s be honest here, there’s no universal answer to which system works best. Now that you’ve seen how each system works, let’s see how to match one to your site.

ICE suits operations’ needs with maximum capacity, with minimal space for larger diameter chains. The Grade 120 material delivers higher working loads in tight access areas where you can’t fit bulkier lifting devices.

Alternatively, VIP works well for applications where field serviceability and lower replacement costs are more essential. Based on our experience supplying both systems to Queensland mining sites, the decision often comes down to your maintenance setup and the variety of work your crew handles.

Consider your team’s capabilities and access to welding equipment when making the choice. And lastly, the time needed for repairs and the risk of extended downtime should also be factored into your decision.